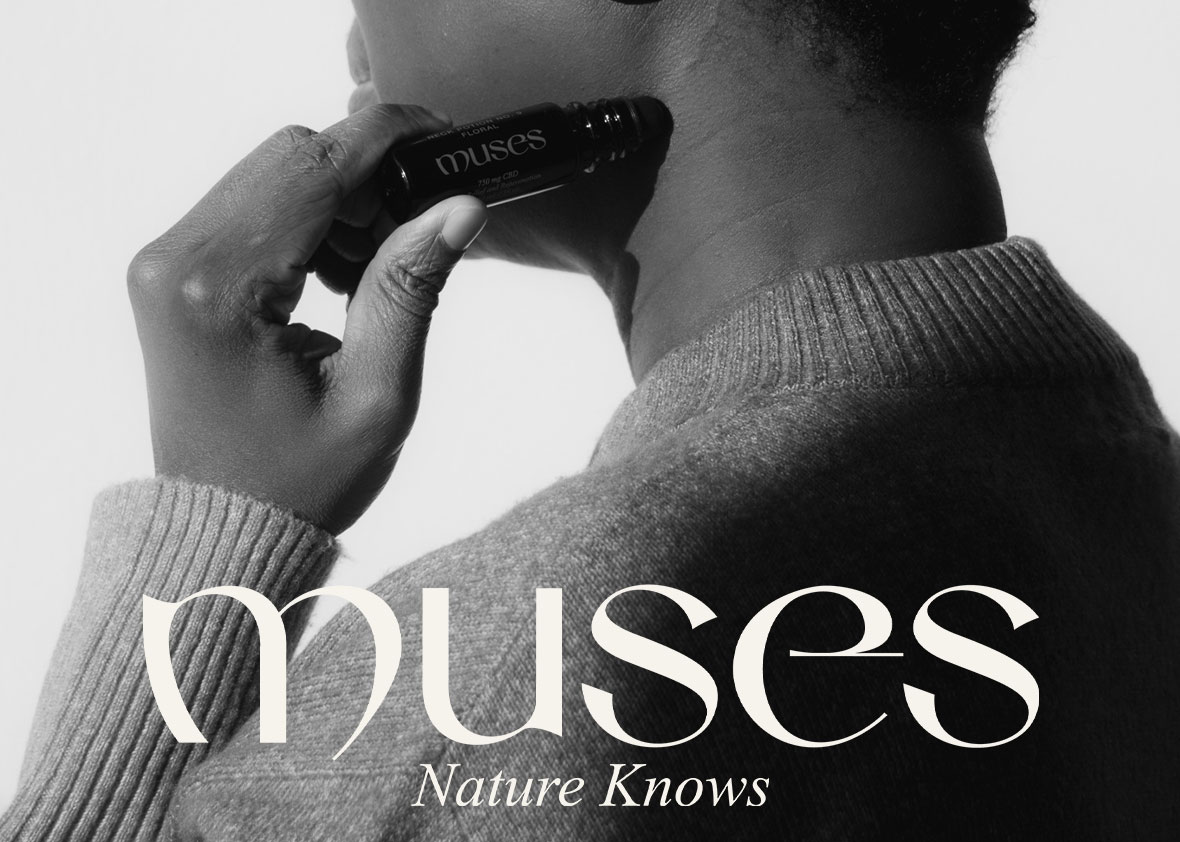

SHOP MUSES

Muses Neck Potion No.9

Muses Neck Potion No. 9™ is the first creation of the Muses collection. This organic roll-on CBD topical is made with an aromatic blend of botanicals to provide pain relief while inspiring your senses. The product celebrates the land of the Hudson Valley in New York, and the power of regenerative farming and plant medicine.