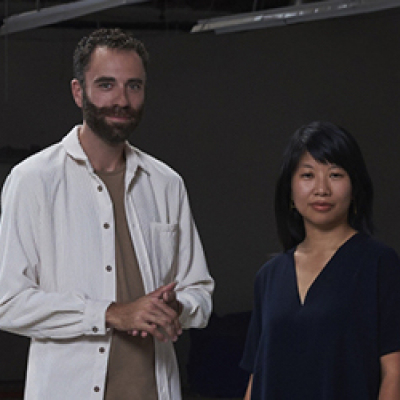

MycoWorks  Co-Founder Sophia Wang first became connected with mycelium as a sculptural medium, and soon learned the true potential of mycelium’s technological applications. CEO Matt Scullin has a PhD in materials science, and was immediately drawn to the use-driven creation process of MycoWorks. Their first product, Reishi™, is paving the way to a more sustainable and regenerative future of fashion. It inspires brands to think about the entire lifecycle of a product, eliminating waste at both the start and end of use. —Charlotte DeFazio

Co-Founder Sophia Wang first became connected with mycelium as a sculptural medium, and soon learned the true potential of mycelium’s technological applications. CEO Matt Scullin has a PhD in materials science, and was immediately drawn to the use-driven creation process of MycoWorks. Their first product, Reishi™, is paving the way to a more sustainable and regenerative future of fashion. It inspires brands to think about the entire lifecycle of a product, eliminating waste at both the start and end of use. —Charlotte DeFazio

How did your journey into mycelium begin?

Sophia Wang: I first became aware of mycelium as a material when I connected with my co-founder, Phil Ross, who had been developing it as a sculptural medium and material for a long time. He and I connected in 2007 when I was his artistic assistant on an exhibit and series of public programs that we were putting together on the history of biotechnology, but framed within the context of art and culture. That’s when I became acquainted with his art practice, which is sculptural and makes use of organic materials by using mycelium. I became aware of mycelium’s potential as a natural material that has many different expressions. It has a wide range of pigmentation and densities and can be rigid, flexible or soft. In 2012, we got back together and started talking about the possibility of starting a company because Phill was receiving interest from brands around the world that wanted to use his mycelium materials in their products and manufacturing. By 2013, we started MycoWorks.

Matt Scullin: I met Sophia and Phil through some mutual friends in San Francisco in 2017. My first reaction was, “A couple folks growing mushrooms in a basement…totally crazy.” But I finally mustered up the courage to go and meet them in person and see the material. As a scientist myself with a formal training and Ph.D. in materials science, I was really taken by what they had created. Other biomaterials companies were focused on the process and the specific molecule that they might be making and finding a use for afterwards, but MycoWorks ended up with this very unique process we call the fine mycelium process, and the resulting material (Fine Mycelium™) is so different and advanced compared to the “mushroom leather” that’s out there. I was compelled by this unique proprietary approach and the resulting performance that it gave. The Fine Mycelium™ cellular structure (the way that we get the cells to intertwine in the mycelium) and the resulting strength and durability was really amazing. Even though the fashion and luxury industries are more and more motivated and propelled by sustainability to change their supply chain and make decisions, at the end of the day, new technologies don’t get adopted unless they perform well. And that’s what I think our differentiation is about. We match performance. We don’t have to compromise performance for sustainability. We can offer both. It’s really the first and only material of the time to do that.

For those unfamiliar with mycelium, what is it and what are some of the many applications of it?

SW: People tend to describe mycelium as the restructure of a mushroom, but it’s more accurate to say that it’s the vegetative part of the organism. Mycelium is the threadlike network that forms the body of the mushrooms. It creates a dense, three-dimensional network. And it’s typically found either underground or living in the substrate in which it grows. There are many applications. Mycelium, particularly materials like reishi, which is the fungus that we use, has a long history of use in traditional Chinese medicine and as an amino supporting agent. It’s long been used in food and medicine. But it also now, by way of innovation, has applications as a material. One of the early applications we were exploring was of creating blocks and boards and rigid objects, like the seat for a stool or a chair, and we created a structure using mycelium with more rigid blocks and bricks. We have also explored the application of mycelium in flexible, foam-like and leather-like materials, which is the basis for the fine mycelium product we’re advancing now, Reishi.

What was the Reishi production process like?

MS: We can’t get into too many details because it’s proprietary, but we make it in a two-foot-by-three-foot tray. We can tune the conditions within this tray—humidity, oxygen content, CO2. The tray is designed in a way where we don’t have to pump gases in or anything like that. The mycelium sort of terraforms its own environment in it. It feeds on a waste biomass of sawdust, allowing that part of the process to be carbon negative. And we form the sheets of Reishi within the tray that we can then harvest. That’s something Phil and Sophia pioneered. The tray-based fermentation of mycelium allows them to grow this wide range of different and interesting materials.

SW: The tray has evolved over time. Initially, we were building them out of wood. And now we have moved to a different material. It came out of Phil’s art practice where we realized mycelium will grow to form. So if you think about a casting material, the mycelium will grow to fill any kind of base. There’s a lot of potential there with customizing the shape in which you’re growing your material.

Reishi has been described as a leather alternative. What are the similarities and differences between Reishi and leather?

MS: We don’t really think of it as an alternative as much as we think of it as another option for fashion designers to choose from. We’re not on a mission to make cowhide leather and we’re not on a mission to make polyurethane pleather. Our goal is not to be the same as those things. On a performance level, we’re really proud of the fact that we perform on a similar level to cowhide. We’re the only biomaterials company to perform at that level, let alone publish any data. But to us, this tray-based system is so much more than leather and anything that exists. The tray-based system allows us to collaborate with fashion designers to grow exactly what they need. We can do things by growing mycelium that you can’t do with plastic or animals. We can grow to different softnesses and firmnesses of material, and to a custom shape. And we’ve really only scratched the surface on the possibilities that mycelium has as a manufacturing platform, which is really what is the most compelling thing about this technology in the long run. We could revolutionize supply chains not only with carbon footprint, but also with creating material that’s made-to-order and custom. I think our customers view this as more of a futuristic option, and one that can in the long run do more and allow you to use it in both the same ways as leather, but also in new ways, which is really exciting.

How has the COVID-19 pandemic changed the fashion world?

MS: From my perspective, we have seen Covid accelerate the interest in sustainability. Obviously, it brought a lot of challenges to every industry. But those aside, we have seen that fashion and luxury brands have had to be very selective, choosing what programs and projects to work on in 2020 under tightening budgets. We’ve seen that across the board. Brands have maintained the commitment to sustainability projects. They are investing heavily. I think that, if anything, 2020 has seen a big acceleration of the interest in sustainable fashion, but also in what companies are actually going to do to get there.

How does Reishi contribute to making the fashion industry more circular?

SW: We are starting with a natural resource that is itself a highly regenerative material, and is actually an agent of environmental regeneration and has in other areas of research been shown to be an agent of bioremediation. So it has the capacity to be a powerful material that has a positive lifecycle plan. We will let our brand partners lead as far as designing their products towards their full lifecycle plan, but we know that what we are contributing to that process is the material that is beneficial to the environment and that can safely biodegrade under the right conditions at the end of the product’s lifecycle.

MS: It’s a step in the right direction for brands who are thinking about end of life for their products. If they’re going to follow through with end-of-life, they have to have the right supply chain. Reishi can play a major role in the design of circular supply chains.

From left: CEO Matt Scullin, Co-Founders Sophia Wang and Phil Ross

Where do you see MycoWorks in the next 5 years?

MS: First and foremost, we see a lot of growth with our recent product. The potential for Reishi to become a significant material and to be widely used in lots of different applications around the world is there, and we’re going to scale to meet that demand. Beyond Reishi, there are a lot of possibilities for other mycelium products that we can make using our Fine Mycelium™ platform for manufacturing. We are generally interested in bringing other mycelium materials to market in the long run that could have properties akin to other materials that could offer added advantages over different types of plastics or even other natural materials. The idea that we can make things that have customizable properties and grow the future materials is really what’s exciting to us in the long run.

SW: What’s really exciting to me is the immense portability of this technology and that mycelium can be cultivated nearly everywhere in the world. The substrate that we use to grow it is a byproduct of agricultural and lumber-based industries. Any place you have that works, you can imagine the production of mycelium-based materials. That has great potential as far as reducing carbon footprint in your global distribution of elements in your supply chain. And it also enables us to imagine a future where mycelium production is ubiquitous in the world.